— High-Quality Centrifuge Solutions Empowered by Welso’s In-House Machining Center

In modern laboratory and industrial testing environments, centrifuges are no longer evaluated solely on whether they can spin. Higher rotational speeds, more stable operation, lower noise levels, and longer service life have become critical criteria for users when selecting centrifuge systems. Behind these performance requirements, the choice of rotor material plays a decisive role.

A centrifuge typically consists of a main unit and detachable rotors. A multifunctional centrifuge can be equipped with different rotor types to meet diverse application needs. For high-speed and ultra-high-speed centrifuges, rotor weight, mechanical strength, and structural stability directly affect operational efficiency and safety.

Why Is Reducing Rotor Weight So Important?

During high-speed rotation, the rotor not only withstands enormous centrifugal forces but also continuously imposes loads on the drive motor, bearing system, and overall machine structure. The lighter the rotor, the lower the system burden, which is reflected in:

Reduced long-term load on the drive motor, extending motor service life

Lower mechanical vibration and noise during high-speed operation

Faster acceleration and deceleration response, improving operational efficiency

Reduced energy consumption and enhanced overall system stability and reliability

As a result, lightweight rotor design has become a key development direction in high-end centrifuge engineering.

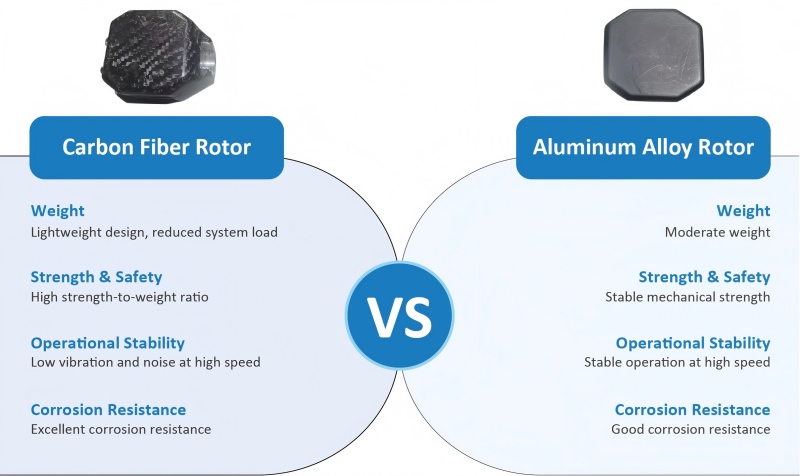

Comparison of Common Centrifuge Rotor Materials

At present, the most common rotor materials used in high-speed centrifuges include aluminum alloy, titanium alloy, and carbon fiber.

Aluminum Alloy Rotors

Aluminum alloy rotors offer light weight, mature manufacturing processes, and moderate cost. They are the most widely used rotor type and are suitable for most routine laboratory and daily centrifugation applications.

Titanium Alloy Rotors

Titanium alloy rotors provide higher strength and excellent corrosion resistance, making them suitable for high-speed operation or environments involving strong acids and alkalis. However, both material and machining costs are relatively high.

Carbon Fiber Rotors

Carbon fiber rotors combine ultra-lightweight construction with exceptional pressure resistance, making them an ideal choice for high-end and ultra-high-speed centrifuges. They are increasingly becoming a key development direction for high-performance centrifuge systems.

Core Advantages of Carbon Fiber Rotors

1. Exceptional Strength-to-Weight Ratio, Significantly Reducing System Load

Carbon fiber materials exhibit extremely high specific strength and stiffness, with strength-to-weight ratios several times higher than those of traditional metal materials. While significantly reducing rotor weight, carbon fiber rotors maintain outstanding structural strength and rigidity, ensuring safer and more stable operation at high speeds.

This advantage is particularly evident in floor-standing high-speed centrifuges and precision-positioning centrifuges, where lighter rotors result in lower mechanical stress and higher long-term reliability.

2. Outstanding Design Flexibility for Optimized Structures

Unlike metal materials, carbon fiber composites allow a high degree of customization through layered composite manufacturing processes. By adjusting fiber orientation, layer thickness, and resin systems, engineers can precisely optimize rotor geometry and mechanical performance for different speeds and load conditions.

This design flexibility enables carbon fiber rotors to achieve complex structures while maintaining an optimal balance between centrifugal force resistance, torsional strength, and thermal stability.

3. Excellent Thermal Performance and Operational Stability

Carbon fiber materials feature a low coefficient of thermal expansion, resulting in minimal dimensional changes under high-speed operation and temperature fluctuations. This helps maintain precise alignment between the rotor and spindle system. In addition, good thermal conductivity supports efficient heat dissipation, reducing performance degradation caused by temperature rise.

4. Superior Corrosion Resistance and Extended Service Life

In humid environments or applications involving chemical samples, carbon fiber demonstrates excellent corrosion resistance. Compared with metal rotors, carbon fiber rotors are less susceptible to corrosion fatigue, require less maintenance, and offer a significantly longer service life.

Welso’s Core Advantage: In-House Carbon Fiber Rotor Machining Center

While many centrifuge manufacturers promote the use of carbon fiber rotors, they often rely on external supply chains, making it difficult to fully control rotor design, machining precision, and product consistency.

What sets Welso apart is our fully equipped in-house machining center.

From material selection and structural design to composite layup, precision machining, and quality inspection, Welso maintains full-process control over carbon fiber rotor manufacturing. This ensures strict consistency in strength, weight, and dynamic balance, while enabling deep optimization between the rotor and the complete centrifuge system.

Currently, Welso carbon fiber rotors have been successfully applied in multiple floor-standing centrifuges and high-end precision-positioning centrifuges. In real-world operation, they demonstrate low noise, high stability, and long service life, meeting the demanding requirements of advanced laboratories and industrial users for performance and reliability.

As centrifuge technology continues to evolve toward higher speeds and greater precision, upgrading rotor materials has become an inevitable trend. With lightweight construction, high strength, and exceptional stability, carbon fiber rotors are redefining performance standards for high-end centrifuges.

Leveraging its in-house machining center and extensive engineering expertise, Welso delivers truly reliable, long-term, high-performance centrifuge solutions through professional manufacturing capabilities.