In environmental analysis, food safety testing, and materials research, microwave digestion has long been recognized as an essential sample preparation method. Among these instruments, high-throughput microwave digestion systems—capable of processing ≥40 samples simultaneously—have become indispensable for laboratories with large sample volumes.

However, “high-throughput” is not simply about loading more vessels. Once the batch size reaches 40 or more, temperature control becomes significantly more complex, pressure safety risks increase sharply, and differences between sample matrices become much more pronounced.

This is why Welso developed a dedicated high-throughput microwave digestion solution—designed to overcome long-standing industry challenges such as inaccurate temperature monitoring, unpredictable pressure fluctuations, and inconsistent digestion of diverse sample types.

Welso’s philosophy is straightforward:

If it’s high throughput, every vessel must receive real monitoring and real protection—individually.

Why High-Throughput Microwave Digestion Requires Stricter Temperature & Pressure Control

1. Multi-ring vessel arrangements create inevitable temperature differences

High-throughput systems are typically arranged in 2 or 3 concentric circles.

Because each ring experiences different electromagnetic energy and cooling conditions, significant temperature variations naturally occur— even for identical samples.

Relying on one “control vessel” to represent the entire batch is scientifically unreliable and potentially unsafe.

2. Large-batch users process diverse sample types

High-throughput users usually face:

Large testing workloads

Highly varied sample matrices

Different reaction behaviors in the same batch

Using a single vessel to represent the temperature/pressure of 39+ other vessels is neither accurate nor acceptable for safety.

3. With 40+ vessels reacting simultaneously, overheating and overpressure risks multiply

Compared to 6–16 vessel instruments, high-throughput digestion faces:

Stronger heat accumulation

Greater difficulty balancing internal pressure

Higher risk that an abnormal vessel triggers a chain reaction

Thus, full-vessel temperature scanning and full-vessel pressure protection are essential safety measures—not optional features.

4. Although high-throughput vessels are structurally simpler, temperature accuracy requirements are higher

High-throughput digestion vessels are designed for:

Faster operation

Lower consumable cost

Simplified workflows

But these advantages raise the bar for temperature uniformity and monitoring precision. Welso’s answer is a fully realized full-vessel temperature control + full-vessel pressure protection system.

Welso Full-Vessel Temperature Control:

True Precision in Every Vessel

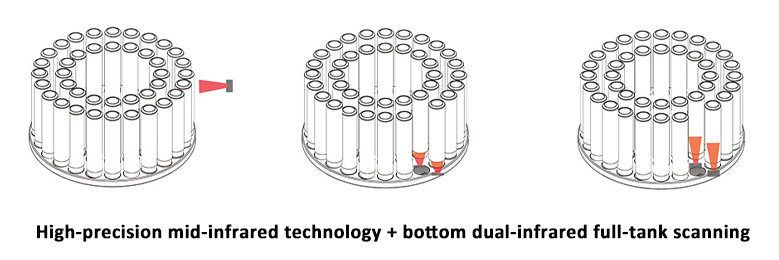

Many brands claim “full-vessel temperature control,” but their technologies differ widely. Welso adopts higher-standard MIR (Mid-Infrared) scanning with dual-point measurement, allowing precise, real-time monitoring of the reaction zone inside each vessel.

Below is a comparison of common industry approaches and Welso’s advantages:

❌ Low-sensitivity NIR + Side-wall Single-Point Monitoring (Not Full-Vessel Control)

Lowest cost

Monitors only outer-ring vessel wall

Not related to actual reaction temperature

Suitable only for rough temperature alarms, not for high-throughput safety

△ High-sensitivity NIR + Bottom Dual-Point Scan (Full Surface Temperature)

Can scan all vessels

Measures material surface temperature, then converts to internal temperature

Accuracy heavily affected by vessel thickness, wear, and aging

Considered an early-generation full-vessel scanning method

✔ Welso: MIR (Mid-Infrared) Penetration Technology + Bottom Dual IR Scanning (Industry Leading)

Welso uses high-precision MIR penetration scanning that:

Passes through vessel material

Directly measures the internal solution temperature

Is unaffected by vessel aging or thickness

Provides significantly higher temperature accuracy

Responds faster to abnormal temperature rises

It is especially effective for:

High-organic matrices

Oil-based samples

Heat-sensitive or complex materials

This MIR technology is currently found only in top-level international models and a handful of manufacturers—Welso among them.

Welso Full-Vessel Pressure Control:

Every Vessel Has Its Own Protection System

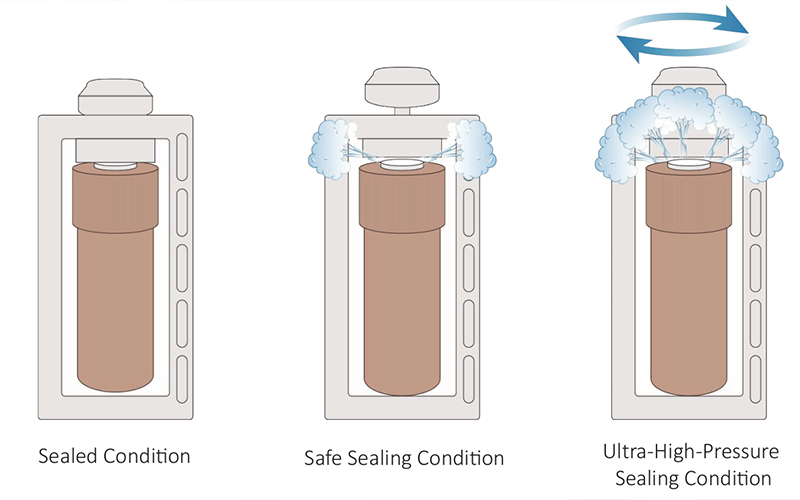

High-throughput digestion brings high pressure risks. Welso therefore equips every vessel with a true independent automatic pressure control module instead of relying on a single control vessel.

Here’s how the industry compares:

❌ Older Method: Non-Quantitative Automatic Venting + Sound Alarm

Low manufacturing cost

Uses sealing deformation to release pressure

Trigger point fluctuates between 10–20 atm

Causes premature pressure drop → insufficient temperature

Oil-based samples often remain unclear

Poor recovery and repeatability

High uncertainty = high risk

✔ Welso: Precision Quantitative Automatic Venting (Advanced Full-Vessel Pressure Control)

Each Welso digestion vessel contains a reusable quantitative pressure module, providing:

Fixed venting threshold at 20 atm

No false triggering

Automatic resealing after pressure drops

Safe operation above 210°C

Complete digestion of oils and other difficult matrices

Higher accuracy and improved recovery rates

Combined with Welso’s acid gas detection system and abnormal sound monitoring, the instrument automatically stops and alarms if multiple vessels vent simultaneously—ensuring full-chamber safety.

Welso High-Throughput Microwave Digestion System:

A Real Solution for High-Workload Laboratories

With industry-leading temperature and pressure control technologies, Welso achieves:

✔ True full-vessel temperature scanning

✔ True full-vessel pressure protection

✔ Excellent compatibility with mixed sample batches

✔ Controllable thermal distribution across multiple vessel rings

✔ Reliable digestion results—even for oils and complex matrices

✔ Simplified structure, easier operation, and lower consumable cost

At Welso, we believe the true value of high-throughput instrumentation is not simply the ability to process more samples.

It is the capability to keep every vessel safe, stable, and accurately monitored—even when 40+ reactions occur simultaneously.

That is the standard Welso commits to—and the standard high-throughput digestion should achieve.