Microwave Digestion System uses microwave heating technology to digest samples in closed vessel under high temperature, high pressure and acid with high concentration. It can keep sample integrity and reduces sample digestion time in volatile elements analysis which meet current requirement for sample digestion.

Superior Digestion Technology Makes Analysis More Accurate

Microwave is a kind of high frequency electromagnetic wave with strong penetrating power which destroys component in the sample by internal heating.

Add moderate acid in digestion vessel and use microwave to dissolve solid samples, turning it into solution for subsequent elemental analysis and composition detection. Add an appropriate amount of acid solution to the digestion tank, and use microwave heating to dissolve or decompose the solid sample, and convert the target substance into a solution state, so as to facilitate the subsequent elemental analysis and composition detection, microwave digestion can greatly reduce the loss of volatile elements, which makes the subsequent analysis results more accurate.

Temperature- Important Parameters in Microwave Digestion

We know that the sample is decomposed at high temperatures, so the temperature has a great influence on whether the sample is completely digested. If the temperature reaches the temperature for complete digestion, digestion solution is clear and element detection value is also stable. Conversely, if the temperature is lower which leads to incomplete digestion of the sample and turbidity of the digestion solution, then measurement accuracy cannot be guaranteed. Therefore, temperature of the microwave digestion system has a great influence on the elemental determination results.

Understanding of Temperature Control Makes Us Easy to Choose Right Microwave Digestion System

Currently main temperature control methods of digestion system are: IR, Thermocouple, Platinum resistance, Optical Fiber control. What are the differences between them? And which method is the best?

Non-contact Temperature Control

IR Temperature Control

Use IR sensor to scan and monitor temperature data in certain distances. Its advantage is to real-time monitor each vessel temperature which is fast, easy to operate and of long serivce life. However, the accuracy of IR temperature control depends on the installation location of the senor. Usually they install on sidewall or on the bottom.

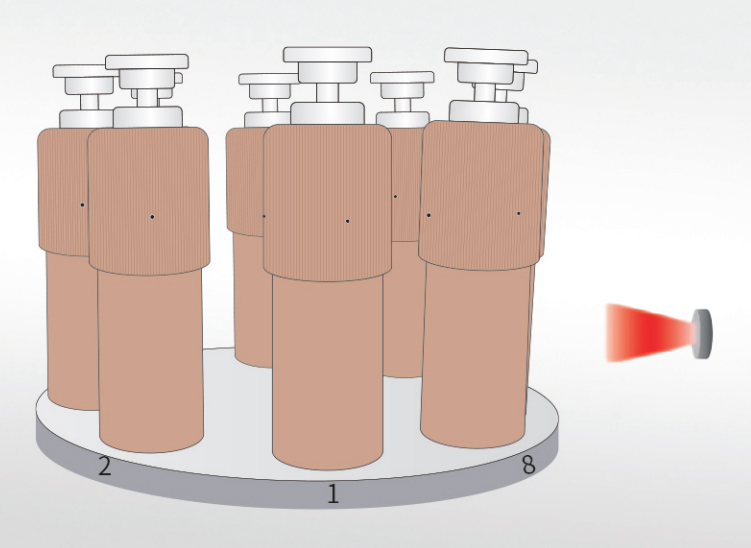

Sidewall IR Control

IR sensor is installed on the sidewall of the microwave digestion chamber. When digestion vessels are placed in 2 circles, the inner circle vessels distance to IR sensor is different which will affect the inner vessel actual temperature greatly.

The liquid level of the vessel needs to reach the height that IR sensor can detect. So the acid volume should not be too less in order to get accurate detection result.

Digestion vessels have inner and outer vessel, IR penetrating outer vessel and detect inner vessel to check temperature. Thus temperature accuracy will be affected by the inner and outer vessel thickness which will cause great tolerance.

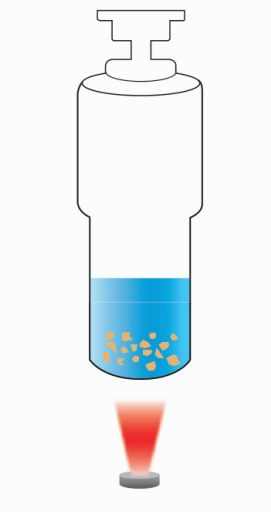

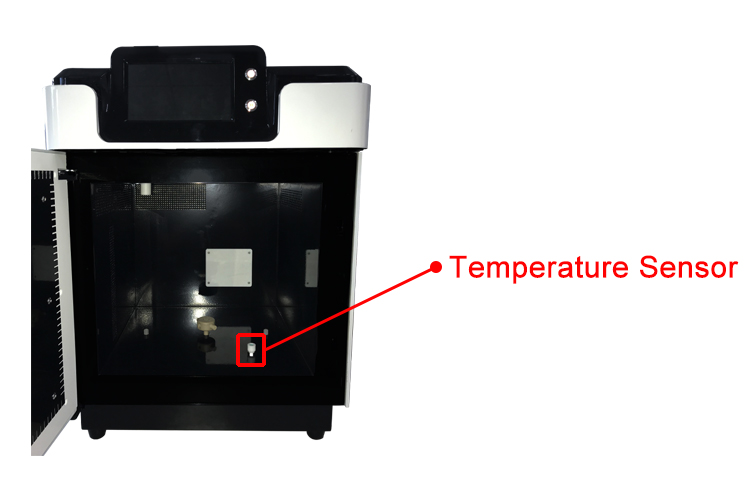

Bottom IR Control

Install IR sensor at the bottom of the chamber and measure temperature from vessel bottom. Outer vessel has a hole at the bottom where IR can easily penetrate and detect solution temperature accurately thus there is no need to have a minimum acid volume.

Bottom temperature measurement will also not be affected by distance. Because distance from each vessel to IR sensor is almost same which ensures temperature uniformity. It avoids the weakness of sidewall IR control and improved accuracy.

Contact Temperature Control

Contact temperature control is a normal temperature measurement method. When contact IR sensor touches sample surface, the current of the sensor will change according to temperature change. It measures current and compare with set temperature so as to get accurate surface temperature.

Thermocouple temperature control, platinum resistance temperature control, and optical fiber temperature control are all contact temperature control methods. Usually contact temperature measurement method will be more accurate than non-contact method. However, contact temperature measurement only contact main vessel. Other vessels will not be contacted. It takes main control vessel as the reference vessel and regards all other vessels are same as main vessel. This requires sample condition and weight in other vessels shall be same as main vessel in order to keep less tolerance between different vessels. But it will be a big challenge to operators if samples are not same materials. Contact temperature control also requires probe to contact samples directly which might cause cross-contamination. Meanwhile, acid in the vessel will also affect probe and easy to cause corrosion which increases maintenance cost.

Which Temperature Control Does Welso Adopt?

Welso microwave digestion system adopts bottom IR temperature control with all vessels scanning which ensures accuracy with 0.1℃. Also, user can add liquid freely without considering temperature control system which is more flexible.

Temperature environment influences a lot on element analysis results. During operation, we shall pay attention to deviation between display temperature and real temperature to avoid affect on further detection.